Demineralising Heating Systems

Heating Water Properly Treated

Maintaining your heating system is crucial for its efficiency and longevity.

While modern heating systems tend to be more efficient and economical to run, they are also more sensitive to the quality of the heating water. Poor quality water can lead to:

Energy efficiency losses of 10 - 20% after the first year

Increased emissions from boiler, negatively impacting the environment

Increase in running and maintenance costs

Increase in chemical use

Water treatment is typically performed during the pre-commissioning stage and continues as an ongoing process to ensure the circulating water remains free of contaminants like particles, bacteria, and other harmful substances that could lead to system failure. Proper treatment helps prevent corrosion and protects metal components, reducing the risk of leaks, efficiency losses, and eventual system breakdown.

Additionally, water treatment prevents scale buildup inside pipes, fittings, and heat exchangers, which otherwise would reduce system efficiency and reliability. It also helps control microbial growth, preventing bacteria and other microorganisms from causing issues such as corrosion and fouling.

By regularly monitoring and maintaining water quality throughout the system's life, you can enhance performance, lower energy costs, reduce repair and maintenance needs, and potentially extend the system’s lifespan.

One key maintenance task is demineralising the water in your heating system. Demineralising is a chemical free solution to treating the water that fills your heating system. Here's why it's essential and how to do it properly.

Why Demineralisation is Important

There are several parameters that will impact the water quality in heating systems. Dissolved oxygen in the water acts as a strong oxidizing agent, which can accelerate corrosion by interacting with metals. Total dissolved solids (TDS) consist of minerals, ions, and other substances dissolved in the water, which increase electrical conductivity and affect the rate of scale formation and corrosion. Water "hardness" refers specifically to the concentration of calcium and magnesium salts, usually in the form of bicarbonates, chlorides, and sulphates, which can accumulate as scale. The pH level, indicating water’s acidity or alkalinity, plays a significant role in corrosion. Lower pH levels (more acidic) tend to increase corrosion by dissolving the protective oxide layer on metals. In contrast, slightly alkaline conditions can enhance the thickness of the protective oxide layer, though excessively high pH can cause other forms of degradation, such as compromising stainless steel components' passivity. Demineralising the heating water in the systems helps with the following:

Prevention of limescale deposits:

According to VDI 2035, high mineral content in water, especially calcium and magnesium, leads to limescale formation. Limescale can clog pipes, reduce heat transfer efficiency, and increase energy consumption.

Reduction of Corrosion:

Minerals in the water increase its electrical conductivity, which accelerates corrosion processes. Using demineralised water significantly reduces the risk of corrosion, extending the life of your heating system components.

Compliance with Standards

Following VDI 2035 guidelines not only ensures optimal system performance but is often required to maintain warranty and guarantee claims. This compliance helps avoid costly repairs and replacements due to scale and corrosion damage.

Steps to Properly Demineralise Your Heating System

Initial Analysis

We measure the electric conductivity, pH value, and total hardness of your heating water. If the parameters exceed the recommended values then demineralisation is necessary.

Cleaning the System

For existing systems, it's essential to clean out any sludge and magnetite deposits. This can involve circulating a cleaning agent through the system for a week or multiple flushes until the water runs clear.

Power Flushing

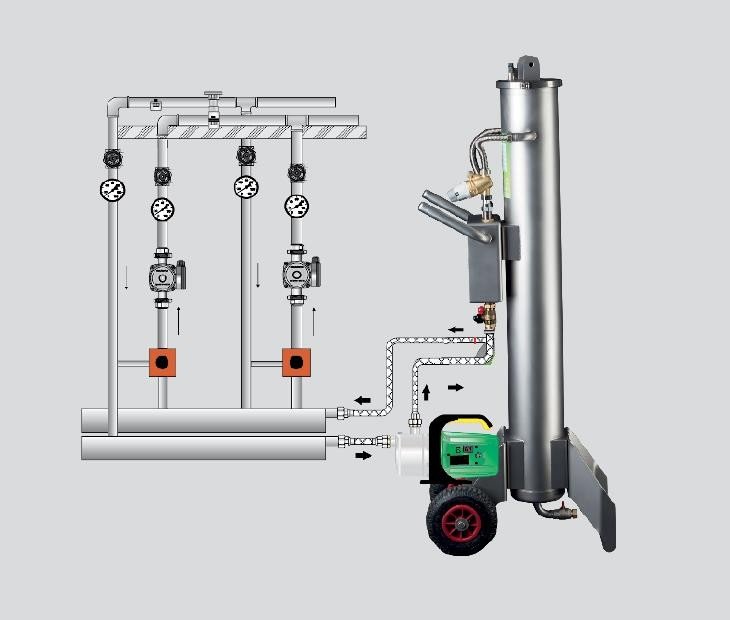

Powerflushing involves flushing each section of the heating system individually. This step ensures that all contaminants are removed before filling the system with demineralised water. Proper equipment like emptying and filling devices is necessary for this step.

Demineralisation

Fill the system with demineralised water, either by using a demineralisation cartridge or a refill station. This step is crucial whether it is a new system or after cleaning and flushing an existing system

Regulation and Top Up

Regularly check and top up the system with demineralised water to maintain optimal water quality. Installing a heating water regulator can help manage the system's pH and prevent new deposits.

Final Analysis

After filling, measure the water parameters again to ensure they meet the required standards. Continue to monitor the pH and conductivity every six months to ensure the system remains in optimal condition.

Following these steps ensures your heating system operates efficiently, reduces maintenance costs, and extends its lifespan.

Maximum Results with Minimal Disruption

To power flush and demineralise your heating system, at TMG Plumbing & Heating Services use machines that work on the CIP (Cleaning In Place) principal. This works with minimal disruption while preventing further blockages and build up, future proofing your heating system.To learn more about Power Flushing your Heating System please click on the download button below.

To learn more about Demineralising your Heating System please click on the download button below.

If you would like to contact TMG Plumbing & Heating Services to enquire about power flushing and demineralising your heating system, flushing radiators or getting your existing underfloor heating system serviced, contact us via the website or call 051 577089.

To read Frequently Asked Questions on Power Flushing your heating system click Power Flushing